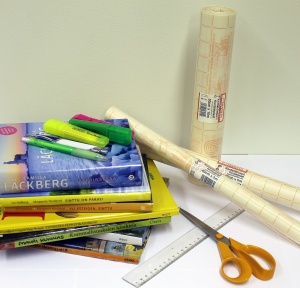

BIO book covering films

Bio book covering films are made from renewable natural resources

The vegetable-based BIO book covering films have been produced with renewable natural resources, without fossil origin raw materials. They provide environmentally friendlier protection for the surfaces of books, magazines and other publications against dirt, moisture, and wear and tear.

We use water based acrylic dispersion adhesives without solvents. All our products are manufactured in Pello, and their raw materials come from Finland and EU. We are continuously developing better and more environmentally friendly solution for book protection.

Versatile BIO book covering films

Our high-quality book covering film is recommended by professional users worldwide. It is extremely easy to use by hand or automatically in book lamination machines. We have developed a short delay in adhesion to enable small adjustments.

Pelloplast book covering films come in different roll widths and lengths. The standard sizes are presented in the following table.

Applications: books, magazines, paperbacks and other publications

| Product | Description |

|---|---|

| 320 | BIO book covering film. Click on the product name (320) for more details. |

Roll sizes of BIO book covering films

| Roll width x length | ||

|---|---|---|

| Roll width x length | ||

| 5 cm x 25 m (5 rll / pkt) | ||

| 7 cm x 25 m (5 rll / pkt) | ||

| 20 cm x 25 m | 20 cm x 50 m | 20 cm x 100 m |

| 25 cm x 25 m | 25 cm x 50 m | 25 cm x 100 m |

| 28 cm x 25 m | 28 cm x 50 m | 28 cm x 100 m |

| 30 cm x 25 m | 30 cm x 50 m | 30 cm x 100 m |

| 32 cm x 25 m | 32 cm x 50 m | 32 cm x 100 m |

| 35 cm x 25 m | 35 cm x 50 m | 35 cm x 100 m |

| 40 cm x 25 m | 40 cm x 50 m | 40 cm x 100 m |

| 45 cm x 25 m | 45 cm x 50 m | 45 cm x 100 m |

| 50 cm x 25 m | 50 cm x 50 m | 50 cm x 100 m |

Also available in other sizes – contact us for more information!

Sugarcane as the raw material of our BIO book covering films

The raw material of the film that is used in our BIO products, are produced of ethanol that is derived from sugarcane. This vegetable-based film is made of a granulate, which is supplied by the world leading biopolymer supplier.

The raw material of the film that is used in our BIO products, are produced of ethanol that is derived from sugarcane. This vegetable-based film is made of a granulate, which is supplied by the world leading biopolymer supplier.

The sugarcane plants absorb carbon dioxide from the atmosphere as they grow. In the production of the vegetable-based films that are used in BIO book covering films, the sugarcane is crushed to produce both cane sugar and ethanol. The bagasse resulting from sugarcane crushing is used to produce steam which supplies the mill’s need for heat and electricity, whilst surplus electricity is sold to the local integrated electrical system. Thereby, the process has a negative carbon footprint, as it absorbs more greenhouse gasses than produces them.

Contact us for a solution that’s a precise fit with your needs.